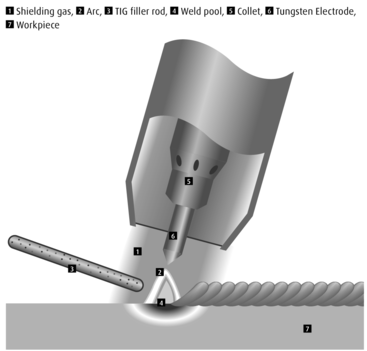

Where the arc makes contact with the workpieces the parent material melts and fuses to form a welded joint. Shielding gas is fed through the torch to protect the weldpool, adjacent material and the tungsten electrode.

The process can be used autogenously (without filler wire) but it is more common to add filler wire manually to increase weld strength and integrity.

Welds produced using the TIG process are usually the highest quality that can be achieved using “common” welding processes.

It’s capacity to be used when welding virtually any material, means argon is the most commonly used shielding gas. However, far better results can usually be achieved by using shielding gas mixtures created for specific materials.

The main drawback with the TIG process is the low deposition rates coupled with high heat input; although this can generally be greatly improved with correct shielding gas selection.