- Official BOC UK Online | Industrial Gases | Products & Solutions | BOConline UK

-

Shop

- Industries

- Processes

- Gases & Equipment

-

Solutions

-

Services

-

Health & Safety

-

Contact & Support

- What's Happening

-

Net Zero Strategies

Cutting Away the Pain

Posted by BOC

“We’ve moved from our nitrogen being a daily problem, to something we’ve hardly spoken about in four years.” Dave Mawer, Owner, D&M Design & Fabrication

D&M Design & Fabrication is one of the UK’s leaders in laser profiling and sheet metal fabrication.

Operating from its workshop near Harrogate in North Yorkshire, the business has grown rapidly over its 11-year history, with a 50-strong workforce producing precision metalwork for industries as diverse as construction, agriculture, food manufacturing and catering.

In the early days as its laser-cutting workload scaled, D&M invested in a precision laser-cutting machine, and the supplier recommended a nitrogen generator to produce the requisite gas.

The hidden costs of on-site nitrogen generation

To begin with, says Dave, the solution worked well for the business. But then they started to grow: “A nitrogen generator is specified to the level of work you’re undertaking, plus a little extra. We were almost victims of our own success – we grew rapidly and after just a year of ownership our nitrogen generator was running 24/7 to keep up. After the second, third and fourth years the bills for repairs were ridiculous – the air compressor alone had every single part replaced four or five times over.”

And it wasn’t just repair costs impacting on the business. Dave and his partner Mike Barratt were having to bring staff in on overtime to make up for delays in production due to breakdowns, while energy costs were eye-wateringly high.

Says Dave: “The generator would break down for a couple of days and we’d have a quiet period where we were unable to cut, then it was all hands on deck to catch up. And it’s not like a generator can simply be switched back on and start working, it would take around ten hours to build up the nitrogen after every engineer visit.

“It got to the point where we had to discuss every job that came in, as to whether we could generate the nitrogen needed. We were switching jobs around; moving onto mild steel and oxygen just to keep up.”

When the five year purchase period was over D&M didn’t hesitate. It was time to turn to bulk supply.

A business transformed through better laser assist cutting gas

BOC specified a bulk tank and nitrogen supply managed via telemetrics. The business’s usage is monitored remotely and the tank refilled as required. BOC is alerted to any unusual activity with an engineer dispatched to site as required, while refills take place at around 11pm to avoid any disruption to D&M’s operations.

“All I know is it works, they fill it up without us here, it’s never gone wrong.” says Dave.

But there are added benefits to bulk supply beyond sustaining gas levels. Since making the switch from on-site generation, Dave and his team have noticed a significant improvement in the purity of their nitrogen.

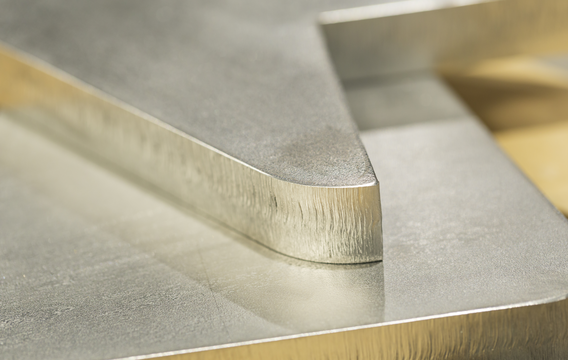

“When we were generating our own nitrogen and cutting thicker stainless steel, the cut edge would often have a pale yellow colour to it, indicating impurity. With bulk supply we get a much better quality cut, even with thicker stainless steel and mild steel – and it’s much cheaper than generating our own nitrogen for the job.”

So much cheaper in fact, that the business has saved almost £14,000 per year on its nitrogen costs by purchasing liquid bulk supply from BOC, when the energy costs, machinery leasing and maintenance of its on-site generator are taken into account.