- Official BOC UK Online | Industrial Gases | Products & Solutions | BOConline UK

-

Shop

- Industries

- Processes

- Gases & Equipment

-

Solutions

-

Services

-

Health & Safety

-

Contact & Support

- What's Happening

-

Net Zero Strategies

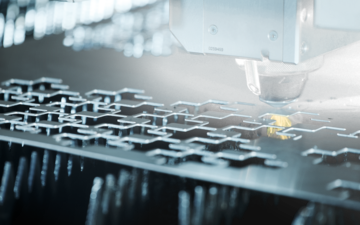

Scaling up your Laser Cutting? It’s Time to Review your Laser Assist Gases Supply

Posted by BOC

Congratulations – you’re ready to scale up your laser cutting capacity. Before you start, have you considered the potential repercussions on your needs for high pressure nitrogen?

Look no further, this blog explores laser cutting gas supply options for growing businesses.

What are my options for increasing my laser assist cutting gas supply?

Many laser cutting businesses start with high purity nitrogen manifolded cylinder pallets (MCPs) – your business may have been the same. And they’re a great starting point. MCPs are an easy option to work out your nitrogen requirements over a couple of months, after which a suitable bulk vessel can be specified.

Bulk vessels themselves can be highly flexible – both in terms of instantaneous flow rates and long-term increase in nitrogen usage. Importantly for businesses increasing cutting capacity, the maximum flow rate doesn’t depend on the size of the tank. Instead it depends on the size of the vaporisers located next to the vessel; comparatively low-cost parts which are easily replaced.

When your usage rate is known, the right size bulk vessel can cope with remarkably large long-term increases in usage. For example, a vessel with an initial delivery frequency of once every two weeks, could easy cope with four times the usage, simply by increasing the delivery frequency to twice weekly. If the tank is fitted with optional telemetry, deliveries can even be arranged automatically, without the tank being checked.

Won’t on-site nitrogen generation give me the flexibility I need?

On-site nitrogen generation can be a good option when fluctuations in flow rates are modest, and where the flow is required round-the-clock and with no, or only a very small long-term increase.

However, they are not well suited to long-term increases in usage, for example if you were to buy one or more additional laser cutting machines. The reason is that on-site nitrogen generators comprise a number of components – the air compressor, molecular sieve container, nitrogen booster compressor and the high-pressure storage bank – that are optimised for a particular flow rate. There is some tolerance, for example through using variable speed compressors and large storage banks, but this is generally inadequate for the scale of growth typically experienced by laser cutting businesses.

In most cases, acquiring additional laser cutting machines also means the significant expense of a larger nitrogen generator. A better option, if you already have a nitrogen generator that you wish to keep, would be to install a bulk vessel to cope with your increase in nitrogen demand. A solution that would also provide the assurance of continued supply when your generator is down for repair or service.

Get the right advice to help with your planning

If you’re thinking about growth in 2021 it’s important to get the right technical support – not only to help determine the best supply option for your new needs, but also to support you as you grow.

BOC’s range of supply options and flexible delivery schedules can grow with you. If you would like us to review your current laser assist cutting gas usage and offer recommendations to help you scale with confidence, speak to us.