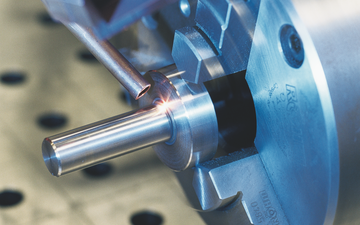

Depending on the thickness of the material, a flat, broad weld seam may be enough; such as the one produced in heat conduction welding with lower power/intensity lasers. If intensity in the focus is sufficiently high, a keyhole is formed that enables deep penetration by the laser beam (deep penetration welding), so that thicker materials can be welded.

Formation of a plasma cloud over the welding spot that can absorb and deflect laser radiation is associated with the forming of the keyhole.

The higher the intensity of laser radiation and the thicker the resulting plasma cloud is, will result in stronger absorption and deflection of the laser radiation by the plasma cloud.

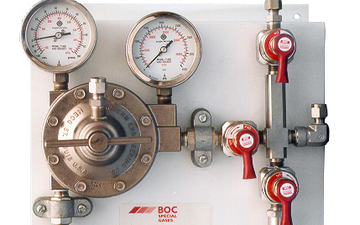

The thickness of the plasma cloud can be influenced by the welding gas. Helium reduces the plasma cloud, argon in turn causes the plasma cloud to expand. The welding gas also serves to protect the welding area, with the heavy and inert argon ensuring that air in the welding area is displaced effectively (flat position). By contrast, helium is a very light, inert gas that rises from the welding area easily.

Both gases are used as a welding gas mixture (3 kW and higher in CO2 lasers) if laser radiation and intensity are high in order to meet both requirements for the welding gas, namely good blanketing of the weld and plasma reduction.